Our Heavy Cranes team sits at the heart of our diverse fleet, allowing our clients to work with the most experienced, most knowledgeable, and importantly, the safest and most trusted team in the lifting industry.

Having worked on many high profile UK lifts with fleet capabilities of up to 1,000 tonnes, we are adept at delivering excellent service on major projects to meet high expectations. We provide the know-how and dedication needed to ensure single or multiple lift, round-the-clock jobs run smoothly and on time.

Get A Quote"*" indicates required fields

Bringing together the full range of our services, including specialist CAD blocks, the Heavy Cranes team creates lift simulations with pin-point precision and forecasts any clashes.

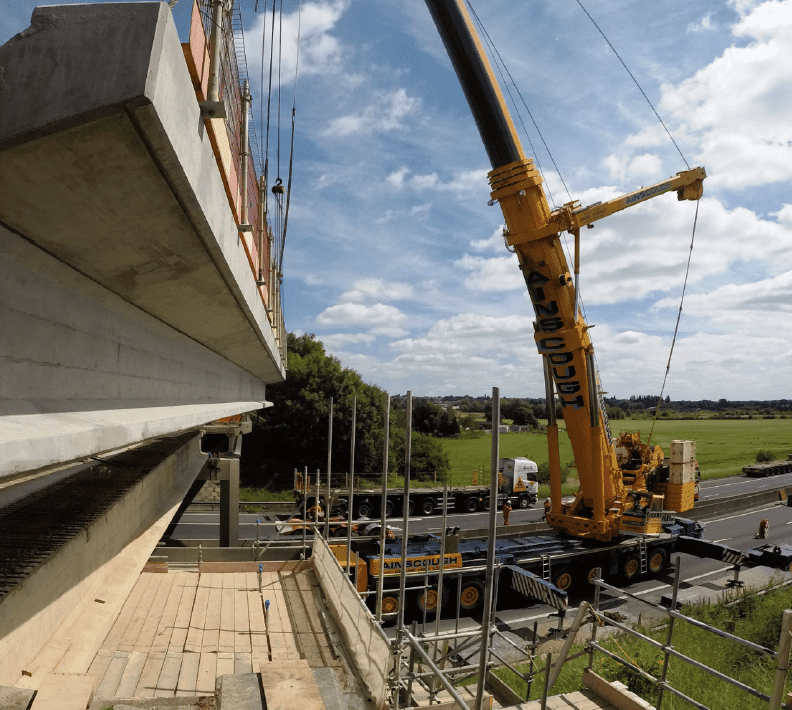

Whether it’s lifting a particularly high bridge into place, dismantling buildings or installing complex industrial machinery, our Heavy Cranes team is the ideal partner for projects that require straightforward completion of challenging lifts.

We deliver heavy crane contract lift and crane hire projects across the UK, offering services including:

Our experienced team of operators, contract lift managers, appointed persons and CAD and BIM technicians assess a range of scenarios in order to develop an efficient and cost-effective solution on a fully insured contract lift basis.

Ainscough Crane Hire is proud of our regularly renewed industry accreditations