Back

Back

At the commencement of the AMP7 programme, United Utilities’ vision was clear - for all parties to collaborate and act as one, in partnership, to be working with our suppliers in a collaborative, proactive manner. By moving towards a true business to business collaborative environment across the supply chain, the aim is to build on the strengths of suppliers and recognise them as an extension of their great service to customers. United Utilities Water, has many site alliances nurtured by the Ainscough Crane Hire team to ensure timely delivery of United Utilities’ framework programme. Working with all our water network partners to take projects through the Solutions Development phases, culminating in project solutions and best value scope pricing, detailed design and completion being carried out as a best value process partner.

Ainscough Crane Hire completed a series of lifts at one wastewater site, northwest of Manchester.

Appointed as part of our collaboration with United Utilities Ainscough Crane Hire was selected to lift and remove and replace storm tank pump equipment weighing almost 2.3 tonnes.

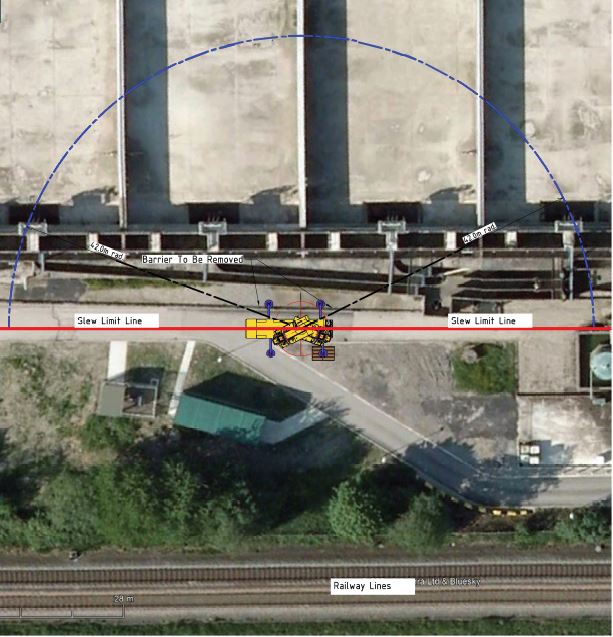

Operators from Ainscough’s Preston depot completed the lifts using two Liebherr LTM 1095, 95-tonne all-terrain mobile cranes; one rigged with a main boom of 54.4m and 23 tonnes of counterweight. The project used the crane slew restrictor to ensure safe use near railway lines. The Slew Limiter system is intended for use on cranes and used in utility maintenance where mobile cranes are restricted to working in confined spaces and there is a requirement to limit the slewing movement of the machine. This restricts the machine to working within the permitted slew sector. As the left or right slew limit is reached a hydraulic solenoid valve is released to cut off the relevant slew hydraulic service, and therefore prevent the machine from entering the exclusion zone. Slew operation in the opposite direction, back into the ‘safe’ zone, is still permitted.

Innovation in design is actively encouraged, as demonstrated by the planning arrangement which was one of the main governing factors that have enabled several projects to progress saving time and money. This is true partnering in operation. Collaboration, innovation, and reviewing critical phases of AMP7 ensure procurement and installation of mechanical and electrical equipment goes to programme, to ensure project deadlines are achieved.