Back

Back

Once complete, the completed terminal will be 150% bigger than the existing Terminal 2 building.

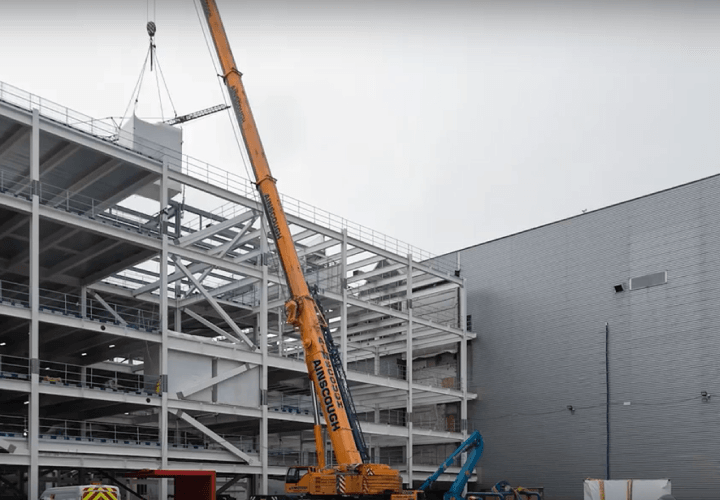

Just 5 months after demolition and piling works, the steelwork on the terminal extension was completed. This paved the way for the first of the project’s three Mega Risers to be installed on-site. Manufactured at the Crown House Technologies manufacturing facility in Oldbury, the Mega Risers are made up of 48 multi-service risers containing ventilation, ductwork, water piping, and electrical containment and heating services. All the services within the Mega Risers are quality inspected in factory conditions before leaving Oldbury. This means that when they arrive on site, they simply need to be lifted into place, connected and put through final commissioning.

The three Mega Risers were manufactured in Oldbury over a 10 week period, and each was installed with the LTM 1200 all-terrain mobile crane on site over a 10 day period. The largest module section is 11m long, 4m wide and 2.8m in depth.

The three-mega risers were manufactured in Oldbury over a 10 week period and each was installed with the LTM 1200 on site over a 10 day period. The largest module section is 11m long, 4m wide and 2.8m in depth.

To ensure the installation was a success, the Ainscough team needed to be absolutely aligned with the client Laing O’Rourke for all operations. Early collaboration with the planning between the project team, Ainscough and Select Plant Hire ensured the installation aligned with the construction programme and that surrounding works were unhindered by the installations.